Tube fouling in your condenser can take a number of different forms, be it silt, sediment, manganese, iron oxide or calcium carbonate, it can have a dramatic negative impact on heat transfer and consequently cleaning factor. If it is bad or dirty enough, it will affect the overall heat rate of the plant and cost the power plant or generator millions of dollars in lost megawatts annually.

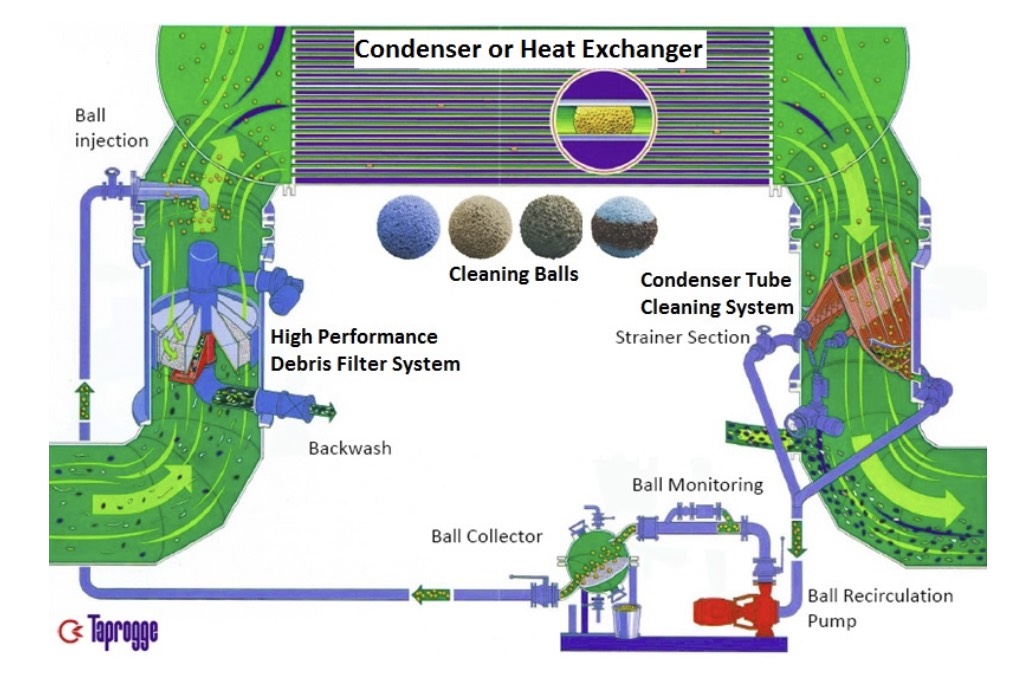

At CIMALTEC we offer equipment and cleaning services for condenser tubes and heat exchangers that will effectively restore your tubes to a new condition, improving the general cleaning factor of the condenser. The clean tubes provide the highest level of heat transfer and are especially beneficial during the hot summer months. Cleaning services may include the supply and installation of automatic cleaning equipment or the maintenance and retrofitting of surface condenser cleaning systems such as Taprogge systems.condensadores de superficie como los sistemas Taprogge.

WE ARE THE EXCLUSIVE DISTRIBUTOR IN BRITISH COLUMBIA, CANADA AND BEFORE THE CFE IN MEXICO.